Mailer Boxes Company

Searching for Cardboard Mailer Boxes for Wholesale Use?

Our Box Manufacturing Company Abilities

We serve a broad range of industries, each with unique needs and custom requests.

Our Packaging Solutions

We serve a broad spectrum of industries and organizations requiring high quality custom packaging for their products and special-use cases. Explore how we can help you with your next packaging project.

Bags

We can design and manufacture high quality custom bags.

Boxes

We can design and manufacture high quality custom boxes.

POP Displays

We can design and manufacture high quality POP displays.

Shippers

We can design and manufacture high quality shippers.

We Can Create Custom Mailers that Help Your Brand and Products Stand Out

Once you contact us and define the sort of packaging you need, then we can provide you with a quote. Contact us today with any questions!

Some of the Industries We Serve

If You Want to Know Where to Buy Mailer Boxes Wholesale, Contact Us

Packaging Services

We offer traditional and unique packaging and boxes that make your brand stand out.

Industry Packaging

We specialize in a creating customized packaging and boxes for a wide range of industries.

Creative Abilities

We can create prototypes, 3D rendering, proofs and have a broad variety of finishing services.

How to Choose Large and Small Corrugated Cardboard Trays?

More Information

Why Custom Mailer Boxes Transform Modern E-Commerce

In today’s competitive e-commerce landscape, the unboxing experience has become a critical touchpoint in the customer journey. Custom mailer boxes represent far more than simple shipping boxes—they serve as brand ambassadors, protection systems, and marketing tools rolled into one. At VSL Packaging, we’ve spent over two decades perfecting the art and science of creating custom mailer boxes that elevate brands while ensuring products arrive safely at their destination.

The rise of direct-to-consumer shipping has fundamentally transformed how businesses approach their packaging needs. No longer can companies rely on generic shipping boxes to deliver their products. Today’s consumers expect an unboxing experience that begins the moment their package arrives. Whether you need subscription boxes for monthly deliveries, gift boxes for special occasions, or durable shipping boxes for everyday e-commerce, this comprehensive guide explores everything you need to know about custom mailer boxes, from material selection and design process to sustainability practices and industry-specific applications.

Understanding Mailer Boxes: Definition, Types, and Applications

What Are Custom Mailer Boxes?

Custom mailer boxes are specialized packaging solutions designed specifically for shipping products directly to consumers or businesses. Unlike traditional shipping boxes, custom mailer boxes typically feature integrated closing mechanisms, superior structural integrity with corrugated cardboard construction, and customization options that transform them into powerful branding tools. These versatile containers combine the protection of corrugated shipping boxes with the presentation quality of retail packaging.

Types of Mailer Boxes and Shipping Boxes

The world of custom mailer boxes encompasses various styles, each suited to different products and shipping needs:

Standard Mailer Boxes: These traditional rectangular custom boxes feature tuck-top closures and are ideal for general merchandise, from clothing to electronics. Their straightforward design makes them cost-effective for high-volume shipping while still offering ample customization opportunities. Most businesses start with standard mailer box sizes before moving to fully custom packaging.

Roll-End Tuck Front (RETF) Mailers: Characterized by their front-locking tuck closure, RETF mailer boxes provide enhanced security and a premium unboxing experience. The roll-end design adds structural strength, making them perfect for heavier items or products requiring extra protection during business days rush shipping.

Literature Mailers: Specifically designed for documents, catalogs, and flat items, literature mailers feature a low profile and variable depth options. These specialized custom boxes protect printed materials from bending and moisture during transit.

Subscription Boxes: The subscription economy has created demand for custom mailer boxes that deliver consistent brand experiences month after month. These subscription boxes often feature unique opening mechanisms, interior CMYK printing, and modular inserts to accommodate varying product assortments.

E-Commerce Shipping Boxes: Optimized for online retail, these custom boxes balance protection, presentation, and postal efficiency. Many e-commerce businesses prefer mailer boxes with frustration-free packaging designs and easy-return functionality to enhance the customer experience while managing shipping costs.

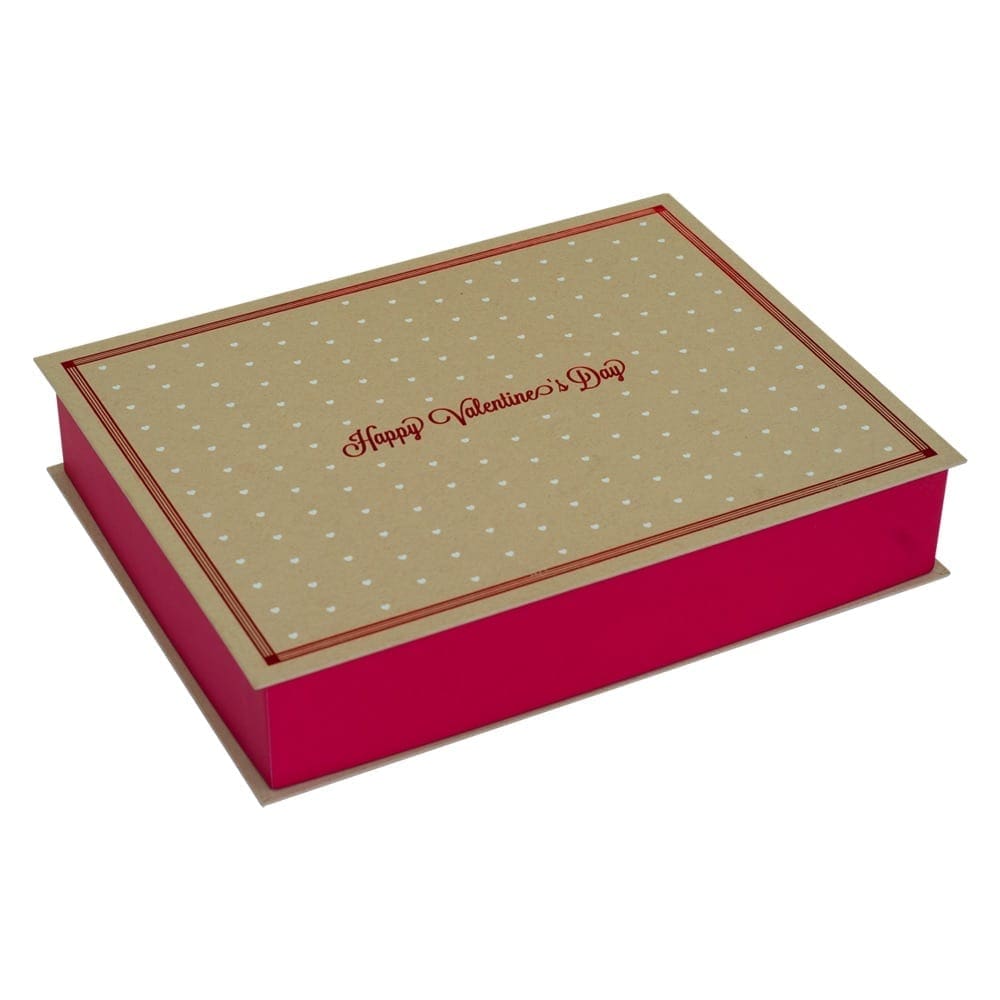

Gift Boxes with Premium Features: For special occasions and luxury products, gift boxes incorporate premium elements like magnetic closures, ribbon pulls, and matte finish options. These custom mailer boxes transform functional packaging into keepsake items that customers treasure long after the unboxing experience.

The Science of Custom Mailer Box Construction

Material Selection and Corrugated Cardboard Engineering

The foundation of any quality custom mailer box lies in its material composition. At VSL Packaging, we utilize advanced corrugated cardboard engineering to create custom boxes that withstand the rigors of modern shipping while maintaining their aesthetic appeal. Our material selection process considers multiple factors:

E-Flute Corrugated Options: The corrugation pattern within corrugated cardboard directly impacts strength and cushioning properties. E-flute corrugated provides excellent printability and structural integrity for lighter products, while B-flute and C-flute options offer superior stacking strength and impact resistance for heavier items. For premium applications requiring extra durability, we often recommend EB-flute (double wall) construction.

Board Grades and Weights: Custom mailer box durability depends significantly on the quality and weight of the corrugated cardboard. We work with various board grades, from lightweight 32 ECT (Edge Crush Test) for small items to heavy-duty 275# test ratings for industrial applications. Our engineering team carefully matches board specifications to product requirements, shipping distances, and handling conditions.

Coating and Treatments: Modern custom mailer boxes often incorporate specialized coatings to enhance performance. Aqueous coatings provide moisture resistance and improve print quality, while UV coatings add durability and visual appeal. For products requiring extended shelf life or international shipping, we offer wax-alternative barrier coatings that maintain recyclability while providing superior protection.

Structural Design Process and Principles

Creating effective custom mailer boxes requires understanding fundamental packaging engineering principles and following a proven design process:

Load Distribution: Proper design ensures weight is distributed evenly across the box structure, preventing collapse during stacking and shipping. We utilize advanced CAD modeling and our design tool to optimize panel dimensions and fold patterns for maximum strength.

Cushioning Integration: Many products require additional protection beyond the box structure itself. Our custom packaging designs can incorporate built-in cushioning features, from corrugated inserts to honeycomb padding systems, eliminating the need for separate void fill materials like dust flaps.

Dimensional Optimization: Shipping costs directly correlate with package dimensions. Our design team specializes in creating custom mailer boxes that maximize protection while minimizing dimensional weight charges. This optimization process can reduce shipping costs by 15-30% compared to standard box sizes.

Design Excellence: Creating Custom Mailer Boxes That Sell

Brand Identity Through Custom Packaging

Your custom mailer box serves as a three-dimensional billboard for your brand. Effective design goes beyond simply printing a logo—it creates an immersive brand experience that resonates with customers long after delivery. Our design process emphasizes several key principles:

Visual Hierarchy: Strategic placement of branding elements, product information, and calls-to-action guides the customer’s eye through the unboxing experience. We employ proven design principles to ensure your most important messages receive maximum attention on every custom box.

Color Psychology and CMYK Printing: Color choices profoundly impact customer perception and emotional response. Our design team leverages color psychology research combined with precision CMYK printing to select palettes that align with brand values and target demographics. Whether you prefer a sophisticated matte finish or vibrant glossy coating, we ensure colors reproduce accurately across all production runs.

Typography and Messaging: The fonts and copy on your custom mailer boxes contribute significantly to brand personality. We help clients develop packaging copy that balances informational needs with emotional engagement, creating connections that extend beyond the transaction.

Print Technologies and Finishing Options for Custom Boxes

Modern printing technology enables unprecedented customization possibilities for custom mailer boxes:

Digital Printing: Ideal for short runs and variable data applications, digital printing offers quick turnaround times and cost-effective customization. This technology excels at producing photo-quality images and enables personalization at the individual custom box level.

Flexographic Printing: For high-volume orders, flexographic printing provides excellent color consistency and cost efficiency. Recent advances in flexo technology rival offset quality while maintaining the speed advantages traditional flexographic processes offer.

Lithographic Lamination: When ultimate print quality is paramount, lithographic lamination combines the precision of offset printing with the durability of corrugated construction. This process produces museum-quality graphics suitable for luxury brands and premium gift boxes.

Special Finishes: Beyond basic printing, numerous finishing options elevate custom mailer box presentations:

- Spot UV coating creates tactile contrast and visual interest

- Foil stamping adds metallic accents for premium appeal

- Embossing and debossing provide dimensional texture

- Soft-touch matte finish coatings deliver a luxurious tactile experience

- Window cutouts showcase products while maintaining protection

- Die-line templates ensure precise cutting and folding

Sustainability in Custom Mailer Box Design

Environmental Responsibility as a Competitive Advantage

Today’s consumers increasingly prioritize environmental responsibility in their purchasing decisions. Sustainable custom mailer box design has evolved from a nice-to-have feature to a fundamental business requirement. At VSL Packaging, we’ve invested significantly in developing eco-friendly custom packaging solutions that meet performance requirements while minimizing environmental impact.

Sustainable Material Innovation for Shipping Boxes

Recycled Content: Our standard custom mailer boxes contain 35-95% post-consumer recycled content, depending on performance requirements. We continuously work with material suppliers to increase recycled content percentages without compromising structural integrity of the corrugated cardboard.

Biodegradable Options: For brands seeking next-level sustainability, we offer custom boxes made from alternative fibers like bamboo, sugarcane bagasse, and wheat straw. These rapidly renewable materials biodegrade completely while providing comparable performance to traditional corrugated materials.

Water-Based Inks and Adhesives: All our printing processes utilize water-based, soy, or vegetable oil inks that minimize VOC emissions and simplify recycling. Similarly, our adhesives are formulated to break down during the recycling process, ensuring clean material recovery for all custom packaging.

Right-Sizing Initiatives: Oversized packaging wastes materials and increases shipping costs. Our design tool specializes in creating perfectly fitted custom mailer boxes that eliminate excess material while maintaining protection. This approach can reduce material usage by up to 40% compared to standard mailer box sizes.

Circular Economy Integration

Forward-thinking brands are embracing circular economy principles in their custom packaging strategies:

Design for Disassembly: We create custom mailer boxes with easy-tear strips and clearly marked recycling instructions, simplifying proper disposal for consumers. Some designs even include perforations that transform shipping boxes into storage solutions, extending their useful life.

Mono-Material Construction: By utilizing single-material designs whenever possible, we ensure custom boxes can be recycled without requiring component separation. This approach significantly improves recycling rates and material recovery quality.

Carbon Footprint Optimization: Our sustainability team can calculate and optimize the carbon footprint of your custom mailer box program, considering factors from material sourcing through end-of-life disposal. We offer carbon-neutral custom packaging options through verified offset programs for brands committed to climate action.

Industry-Specific Custom Mailer Box Solutions

E-Commerce and Retail Shipping Boxes

The e-commerce revolution has created unique packaging needs that traditional boxes weren’t designed to address. Modern e-commerce custom mailer boxes must protect products through complex distribution networks while creating memorable unboxing experiences that drive social sharing and repeat purchases.

Fashion and Apparel: Clothing retailers require custom mailer boxes that prevent wrinkles while showcasing brand aesthetics. Our fashion-specific designs incorporate tissue paper anchoring points, integrated hangers, and ventilation features that maintain garment freshness during shipping. Many include tear-away strips that convert shipping boxes into gift boxes, adding value for customers.

Electronics and Technology: Tech products demand superior protection against shock, vibration, and static discharge. Our electronics custom boxes feature multi-layer cushioning systems, anti-static coatings, and tamper-evident closures. Custom inserts precisely position products and accessories, eliminating movement during transit while creating organized, professional presentations.

Beauty and Cosmetics: The beauty industry’s emphasis on luxury and experience requires custom mailer boxes that feel as premium as the products inside. We create designs with magnetic closures, ribbon pulls, and interior CMYK printing that transform functional packaging into keepsake boxes. Special coatings protect against oil and liquid spills while maintaining aesthetic appeal with options like matte finish or gloss varnish.

Food and Beverage Shipping Solutions

Shipping consumable products presents unique challenges requiring specialized custom mailer box solutions:

Temperature Control: Our insulated custom boxes incorporate phase-change materials and reflective linings to maintain temperature stability during shipping. These designs can keep products frozen for up to 72 hours or maintain refrigerated temperatures for five business days, enabling nationwide distribution of perishable goods.

Moisture Management: Food products often generate condensation that can compromise packaging integrity. We’ve developed moisture-wicking custom mailer box designs that channel condensation away from critical areas while maintaining food safety standards. Grease-resistant coatings prevent oil migration from compromising corrugated cardboard structure.

Regulatory Compliance: Food packaging must meet strict FDA requirements for direct food contact. Our food-grade custom boxes utilize approved materials and barrier coatings that prevent migration while maintaining recyclability. Clear labeling systems ensure compliance with nutritional information and allergen disclosure requirements.

Pharmaceutical and Healthcare Custom Packaging

Medical products require custom mailer boxes that prioritize security, compliance, and protection:

Child-Resistant Features: We design custom boxes with integrated child-resistant mechanisms that meet CPSC requirements while remaining accessible for elderly patients. These features include push-and-turn closures, sequential opening steps, and strength-based barriers.

Temperature Monitoring: Pharmaceutical custom mailer boxes often incorporate temperature indicators that provide visual confirmation of cold chain maintenance. These low-cost additions offer peace of mind for both shippers and recipients, particularly for temperature-sensitive medications.

Serialization and Track-and-Trace: Modern pharmaceutical regulations require detailed tracking capabilities. Our custom boxes can incorporate RFID tags, QR codes, and serialized printing that enable full supply chain visibility while combating counterfeiting.

The Economics of Custom Mailer Boxes

Understanding Total Cost of Ownership and Shipping Costs

When evaluating custom mailer box options, successful businesses look beyond unit price to consider total cost of ownership and overall shipping costs:

Damage Reduction: Quality custom mailer boxes dramatically reduce product damage rates compared to generic packaging. Even a 1% reduction in damage claims can offset premium custom packaging costs for high-value items. Our reinforced designs typically achieve 60-80% damage reduction compared to standard shipping boxes.

Shipping Optimization: Dimensional weight pricing means that mailer box sizes directly impact shipping costs. Our custom-fit mailer boxes eliminate wasted space, potentially reducing shipping expenses by 20-35%. For businesses shipping thousands of packages monthly, these savings quickly exceed any premium for custom boxes.

Labor Efficiency: Well-designed custom mailer boxes reduce packing time and complexity. Features like auto-locking bottoms, integrated tape strips, and pre-positioned inserts can cut packing time by 40-50%. This efficiency improvement translates to significant labor cost savings and increased throughput capacity during busy business days.

Marketing Value: Custom mailer boxes serve as mobile advertisements, generating brand impressions throughout the delivery journey. Studies indicate that branded custom packaging increases customer retention by 30% and social media sharing by 40%. This marketing value often exceeds the incremental cost of customization.

Volume Considerations and Quantity Orders

Understanding volume dynamics helps optimize custom mailer box investments:

Prototype and Short Runs: Digital production technologies enable cost-effective short runs starting at just 100 units. This capability allows thorough testing before committing to large quantity orders and enables seasonal or limited-edition custom packaging programs.

Standard Production Runs: Most custom mailer box programs achieve optimal pricing at 5,000-10,000 unit quantities. At these volumes, setup costs are efficiently amortized while maintaining inventory flexibility for various mailer box sizes.

High-Volume Programs: For shipments exceeding 50,000 units annually, dedicated tooling and automated production lines deliver significant per-unit savings. We offer vendor-managed inventory programs that optimize cash flow while ensuring consistent supply of your custom boxes.

Quality Control and Testing Standards

Ensuring Consistent Performance in Every Custom Box

Quality custom mailer boxes require rigorous testing and quality control throughout the production process:

Material Testing: Every batch of corrugated cardboard undergoes comprehensive testing for burst strength, edge crush resistance, and moisture content. We maintain detailed records enabling full traceability from raw materials through finished custom packaging products.

Box Compression Testing: Finished custom mailer boxes undergo compression testing simulating real-world stacking conditions. We test to 5x expected loading conditions, ensuring substantial safety margins for challenging shipping environments and various shipping box configurations.

Drop and Vibration Testing: Our testing lab simulates the shocks and vibrations encountered during shipping. Custom boxes undergo sequential drop tests from various angles and extended vibration testing replicating long-distance transportation across multiple business days.

Environmental Conditioning: Custom mailer boxes must perform consistently across various environmental conditions. We test performance after exposure to high humidity, temperature extremes, and UV radiation, ensuring reliable protection regardless of shipping conditions or destination.

Continuous Improvement in the Design Process

Our commitment to quality extends beyond initial production:

Customer Feedback Integration: We systematically collect and analyze customer feedback, using insights to refine designs and processes continuously. This feedback loop has driven numerous innovations in our custom packaging, from easier-opening mechanisms to improved stacking features.

Supply Chain Monitoring: Regular audits of our material suppliers ensure consistent quality and sustainable practices throughout the supply chain. We maintain redundant supplier relationships to prevent disruptions while driving continuous improvement in corrugated cardboard quality.

Technology Advancement: Ongoing investments in production technology enable increasingly precise manufacturing and expanded customization options. Recent additions include laser cutting systems for intricate custom box designs and automated inspection systems that ensure consistent quality across all quantity orders.

Future Trends in Custom Mailer Box Design

Smart Packaging Integration for Subscription Boxes

The future of custom mailer boxes includes intelligent features that enhance functionality and customer engagement:

NFC and RFID Integration: Near-field communication chips embedded in custom boxes enable interactive experiences, authentication, and supply chain tracking. Customers can tap their phones to access product information, assembly instructions, or exclusive content directly from their subscription boxes.

Augmented Reality Experiences: AR-enabled custom mailer boxes transform static packaging into interactive experiences. Scanning box graphics with smartphone apps can trigger 3D animations, virtual try-ons, or immersive brand stories that elevate the unboxing experience.

Connected Packaging Platforms: IoT-enabled custom boxes provide real-time shipping updates, temperature monitoring, and tampering alerts. These capabilities particularly benefit high-value shipments and temperature-sensitive products requiring careful handling.

Advanced Personalization and Custom Packaging

Digital printing advances enable unprecedented personalization possibilities for custom mailer boxes:

Variable Data Printing: Every custom box can feature unique graphics, messages, or offers tailored to individual recipients. This capability transforms packaging into a powerful direct marketing channel using CMYK printing technology.

Regional Customization: Brands can efficiently produce region-specific custom packaging variations, incorporating local languages, cultural elements, or promotional offers without maintaining extensive inventory of different mailer box sizes.

Seasonal and Event-Based Designs: Quick-turn digital production enables timely custom box updates for holidays, sporting events, or cultural moments, keeping brands relevant and engaging throughout the year.

Sustainable Innovation in Shipping Boxes

Environmental considerations will continue driving custom mailer box innovation:

Bio-Based Materials: Emerging materials derived from agricultural waste, mycelium, and other biological sources promise carbon-negative custom packaging solutions. These materials offer comparable performance to traditional corrugated cardboard while actively sequestering carbon.

Chemical Recycling Integration: Advanced recycling technologies will enable higher-quality material recovery, allowing increased recycled content in custom boxes without performance degradation.

Reusable Systems: Some brands are exploring returnable custom mailer box programs that amortize packaging costs over multiple uses while dramatically reducing environmental impact. These systems work particularly well for subscription boxes and regular shipments.

Partnering with a Professional 3D Design Studio for Packaging Success

Why Choose VSL Packaging for Your Custom Mailer Box Needs

With over 20 years of experience in custom packaging solutions, VSL Packaging has established itself as a trusted partner for businesses seeking exceptional custom mailer boxes. Our comprehensive approach combines technical expertise, creative design process capabilities, and operational excellence to deliver packaging that drives business results.

End-to-End Capabilities: From initial concept through final delivery, we manage every aspect of your custom mailer box program. Our integrated services include structural design using advanced design tools, graphic design with CMYK printing expertise, prototyping, testing, production, and fulfillment, ensuring seamless execution and consistent quality.

Industry Expertise: Our team includes packaging engineers, designers, and industry specialists who understand the unique challenges facing your business. This deep expertise enables us to anticipate packaging needs and propose custom box solutions that others might overlook.

Innovation Partnership: We view ourselves as innovation partners, not just box suppliers. Our R&D team continuously explores new materials, technologies, and techniques, ensuring our clients benefit from the latest advances in custom packaging and corrugated cardboard engineering.

Scalable Solutions: Whether you need 100 prototype custom boxes or 10 million production units, our flexible manufacturing network scales to meet your quantity order needs. We maintain relationships with specialized producers for unique requirements while operating efficient high-volume facilities for standard products.

Sustainable Leadership: Our commitment to sustainability goes beyond compliance to actively advancing environmental packaging practices. We help clients achieve their sustainability goals while maintaining the performance and aesthetics their brands require in every custom mailer box.

Getting Started with Custom Mailer Boxes

The Design Process for Your Custom Packaging

Creating exceptional custom mailer boxes begins with understanding your unique requirements:

Discovery Phase: Our design process starts with comprehensive discovery sessions exploring your products, brand values, distribution channels, and customer expectations. We analyze competitive packaging and identify opportunities for differentiation in your custom boxes.

Concept Development: Our 3D design studio creates multiple concept directions exploring different structural and graphic approaches. These concepts balance your functional requirements with brand expression and budget considerations for various mailer box sizes.

Prototyping and Testing: Before committing to production, we create functional prototypes using die-line templates for hands-on evaluation. These prototypes undergo rigorous testing to ensure they meet all performance requirements while delivering the desired unboxing experience.

Refinement and Optimization: Based on prototype feedback, we refine designs to optimize every aspect from protection to presentation. This iterative design process ensures the final custom packaging exceeds expectations.

Production Planning: Our production team develops detailed manufacturing plans ensuring consistent quality and timely delivery. We coordinate all aspects from material procurement through shipping logistics, managing everything from shipping costs to delivery timelines.

Making the Investment in Custom Packaging

Investing in custom mailer boxes represents a strategic decision that impacts multiple aspects of your business:

Brand Differentiation: In crowded markets, custom packaging often provides the clearest differentiation opportunity. Custom mailer boxes communicate quality and attention to detail that generic shipping boxes cannot match.

Customer Loyalty: Memorable unboxing experiences create emotional connections that drive repeat purchases and word-of-mouth referrals. Studies show that 52% of consumers are more likely to make repeat purchases from brands that deliver premium custom packaging experiences.

Operational Efficiency: Well-designed custom mailer boxes streamline fulfillment operations, reduce damage claims, and optimize shipping costs. These operational improvements often offset premium packaging costs while enhancing customer satisfaction.

Sustainable Growth: Investing in sustainable custom packaging positions your brand for long-term success as environmental considerations become increasingly important to consumers and regulators alike.

Conclusion: Elevating Your Brand Through Strategic Custom Packaging

Custom mailer boxes represent far more than functional shipping containers—they serve as brand ambassadors, customer experience enhancers, and operational efficiency tools. In an era where e-commerce continues its explosive growth and customer expectations reach new heights, investing in strategic custom packaging solutions has become essential for competitive success.

The journey from generic shipping boxes to custom mailer solutions that delight customers and drive business results requires expertise, creativity, and commitment. At VSL Packaging, we bring together decades of experience, cutting-edge technology including advanced 3D design studio capabilities, and passionate dedication to help businesses transform their packaging from a necessary expense into a strategic advantage.

Whether you’re launching a new product line with subscription boxes, refreshing your brand image with updated gift boxes, or seeking to optimize your packaging operations with better shipping solutions, custom mailer boxes offer unprecedented opportunities to stand out in the marketplace. The investment in professional packaging design and quality manufacturing pays dividends through enhanced brand perception, reduced operational costs, and increased customer loyalty.

Ready to transform your shipping experience with custom mailer boxes that set your brand apart? Contact VSL Packaging today to begin exploring how strategic custom packaging can accelerate your business growth. Our team of experts stands ready to guide you through every step of the design process, from initial concept to delivered success. Together, we’ll create custom mailer boxes that don’t just ship products—they deliver unforgettable unboxing experiences that customers remember and share.