Medical Packaging Company

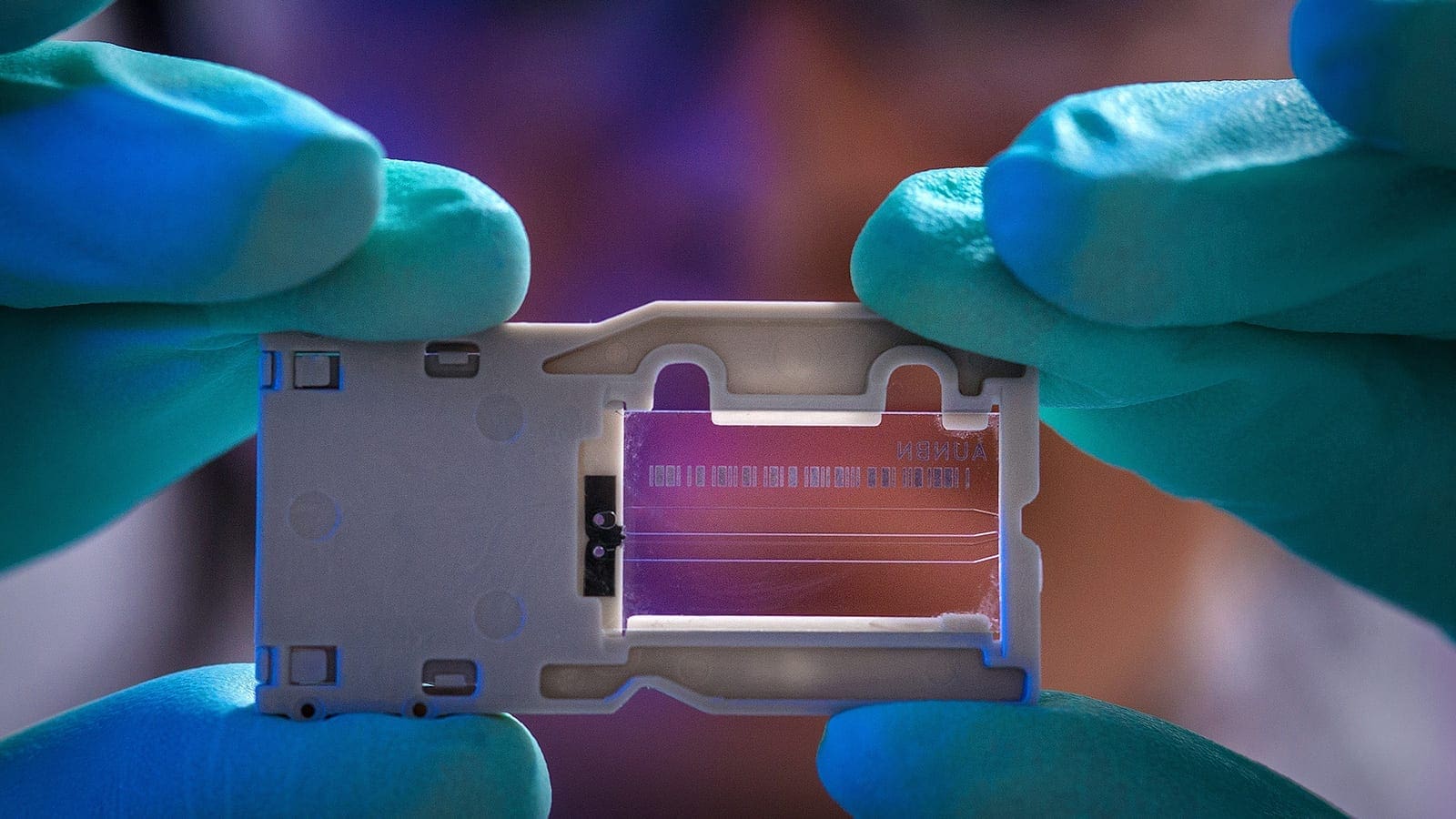

Need Innovative Custom Medical Device Packaging?

Some of the Industries We Serve

Our Packaging Solutions

We serve a broad spectrum of industries and organizations requiring high quality custom packaging for their products and special-use cases. Explore how we can help you with your next packaging project.

Bags

We can design and manufacture high quality custom bags.

Boxes

We can design and manufacture high quality custom boxes.

POP Displays

We can design and manufacture high quality POP displays.

Shippers

We can design and manufacture high quality shippers.

We Excel in Manufacturing Custom Packaging Boxes, Bags, and Containers

Packaging Services

We offer traditional and unique packaging and boxes that make your brand stand out.

Industry Packaging

We specialize in a creating customized packaging and boxes for a wide range of industries.

Creative Abilities

We can create prototypes, 3D rendering, proofs and have a broad variety of finishing services.

Our Customization Abilities

Choose Quality Packaging for Your Medical Brand

VSL Packaging custom medical packaging is the perfect way to package, ship and sell your medical devices, pills, and products. VSL Packaging is an established, reputable brand in custom printed pills packaging and providing high quality customized medical boxes in various sizes, shapes, colors, and styles.

More Information

Understanding Custom Medicine Packaging Solutions

Importance of Secure Packaging in Healthcare

Custom healthcare packaging solutions are key for keeping healthcare products safe and effective. Secure packaging solutions help protect patients by preventing contamination and damage during shipping and storage. Companies need solid pharmaceutical packaging protection solutions to keep product quality high.

Good protective packaging solutions use features like tamper-evident seals. These seals show if someone has tried to open the package without permission. Compliance labels are important too; they provide crucial information like how to use the product and when it expires. Quality assurance in packaging means that these products can safely reach their destination while maintaining their intended effectiveness.

Overall, secure healthcare packaging solutions are essential for product packaging, a shipper box, or customized poly mailers. It helps protect both patients and healthcare workers by reducing risks linked to damaged or unsafe products.

Compliance with FDA and GMP Standards

In the medical industry, following regulations is a must. FDA compliance guarantees that all medical packaging solutions meet federal safety rules meant to protect public health. This includes guidelines on the materials used, how products are labeled, and design standards.

Good Manufacturing Practices (GMP) help maintain quality throughout production. These standards also cover UDI (Unique Device Identification) requirements. This system allows for better tracking of medical devices through serialization in the packaging.

By sticking to FDA and GMP guidelines, manufacturers can make sure their products meet high-quality standards. This builds trust among consumers regarding safety and reliability.

Enhancing Brand Identity Through VSL Packaging Solutions

Custom medicine packaging solutions not only serves functional needs but also acts as a strong branding tool for companies in the pharmaceutical sector. High-quality healthcare packaging helps boost brand identity by showing a commitment to professionalism and excellence.

Using custom designs lets companies stand out from their competitors while still meeting required labeling standards. More people today care about eco-friendly choices, so offering biodegradable or recyclable materials can really improve how customers see your brand.

In the end, effective branding through custom healthcare packaging solutions can strengthen consumer confidence. It’s an important part of marketing strategies within healthcare.

Types of Medical Packaging Solutions

Protective Boxes for Pharmaceuticals and Devices

Protective packaging solutions are key in the medical field, especially for pharmaceuticals and medical devices. These boxes keep products safe during storage and transport. High-quality healthcare packaging solutions use strong materials that guard against damage, moisture, and contamination.

Pharmaceutical packaging solutions often have designs made for specific product needs. For example, rigid boxes help support fragile items like vials or syringes. With durable medical packaging solutions, healthcare providers can reduce the chances of losing products to breakage or spoilage.

Flexible Pouches for Medical Supplies

Flexible pouches provide a handy option for many medical supplies. They are lightweight but still tough enough to keep items safe from tampering. Custom medical and healthcare packaging allows manufacturers to make pouches in various sizes and styles.

Eco-friendly medical packaging is becoming more popular as companies look for green options. Many flexible pouches are now made from recyclable materials, which does not affect quality or strength. This change meets rules and appeals to buyers who care about the environment.

Sterile Packaging Options

Sterile healthcare packaging is vital to stop contamination of sensitive medical products like surgical tools and drugs. Aseptic methods such as ethylene oxide sterilization or gamma radiation effectively kill harmful germs while keeping the product safe.

Steam sterilization is another common method that achieves high sterility through heat under pressure. Each sterile option requires careful thought about how it works with the material of the packaged item and its use in healthcare settings.

Child-Resistant and Tamper-Evident Features

Child-resistant healthcare packaging is important for patient safety because it helps lower the risk of kids accidentally swallowing medicines or harmful substances. Adding tamper-evident features increases security by showing clear signs if a package was opened before it reached the consumer.

Compliance labels must give clear usage instructions while following strict guidelines from health authorities—this makes sure safety measures are in place along with necessary information about how to take medications correctly, helping protect patients’ health.

Blister and Modified Atmosphere (MAP) Packing

Blister packing works well for pharmaceuticals where each dose needs protection until it’s time to use it. For example, tablets packed in clear plastic cavities sealed with foil backing keep moisture and air away, helping them last longer.

Modified atmosphere packaging (MAP) uses controlled gases inside packages to extend shelf life significantly—perfect for goods that need to stay fresh longer without losing quality during shipping across healthcare networks around the world.

Cleanroom and Shipping Protection

Cleanroom packaging meets strict healthcare cleanliness standards during production—this is especially important when dealing with sterile environments in hospitals or labs. This ensures smooth operations while handling critical components used in these settings.

Shipping protection helps keep valuable items safe from damage while being transported using strong outer layers made according to industry standards. This supports successful transport practices for organizations dedicated to delivering excellent service consistently over time.

Sustainable Medical Packaging Innovations

Eco-Friendly Materials in Healthcare Packaging

The need for eco-friendly healthcare packaging is growing. Healthcare brands want sustainable solutions. Biodegradable healthcare packaging made from plant-based materials is a great option. This kind of healthcare packaging breaks down naturally over time, which helps reduce waste in landfills.

Recyclable packaging is also key. It lets consumers dispose of materials responsibly and encourages recycling habits.

Sustainable materials like recycled paperboard and compostable plastics are becoming popular. These materials lower environmental impacts and meet strict safety rules in medical settings. By using eco-friendly healthcare packaging, companies improve their image while helping the environment.

Minimizing Waste with Reusable Designs

Medical waste reduction is really important for sustainability in healthcare. Using reusable designs can greatly reduce single-use items that create waste. For example, durable containers meant for multiple uses help healthcare providers use resources better.

Reusable designs also lessen the overall environmental impact of packaging. They cut back on production needs and material use. This idea supports a circular economy where products get reused instead of thrown away after one use.

Balancing Sustainability and Product Protection

While focusing on sustainability, product protection can’t be ignored. Durable healthcare packaging keeps products safe during transport and storage without losing quality or safety. High-quality materials act as barriers against contamination and meet compliance labels from regulatory bodies like the FDA.

Companies should include risk management strategies in their sustainable practices. It’s important to ensure that environmental goals align with patient safety needs. Finding creative ways to balance these aspects helps companies stay committed to sustainability while ensuring reliability and performance in their medical products.

Customization Options for Medical Packaging

High-Quality Printing and Branding

High-quality printing plays a big role in medical product branding. Custom labels for medical products help people identify what’s inside. They also share key information about usage and dosage. Plus, they must follow FDA compliance rules. Good healthcare packaging combines branding with clarity. This builds consumer trust and helps brands stand out.

Using advanced printing methods lets manufacturers create eye-catching colors and clear images. This includes logos and safety instructions that are essential for users. Following FDA guidelines makes sure all printed materials meet standards. This is important for keeping a good reputation in the industry.

Tailored Sizes and Configurations

Custom healthcare packaging comes in sizes that fit specific needs across different uses. Durable healthcare packaging protects sensitive products during transport. It also needs to work well with the materials used to make them.

Here are some important points about protective packaging:

- It keeps items safe from moisture.

- It stops contamination from affecting the products.

- Custom dimensions reduce waste.

- This can help lower shipping costs.

Adding features like inserts or compartments makes packaging even more useful. These features give extra protection to fragile items or keep parts separated inside a package.

Incorporating Anti-Counterfeit Measures

With the rise of counterfeit medications, using anti-counterfeit measures in healthcare packaging is very important. Tamper-proof packaging helps assure consumers that their products are safe to buy.

Serialization helps fight counterfeiting by giving each package a unique identifier under UDI requirements set by regulatory agencies. This allows better traceability throughout the supply chain security, which strengthens risk management plans against fraud.

Adding these security features not only protects patients but also boosts brand reputation through a commitment to safety standards.

Regulatory Considerations in Medical Packaging

Proper Labeling and Dosage Instructions

Proper labeling is super important for safe and effective use of medical products. Compliance labels need to follow strict healthcare regulations. This includes clear dosage instructions and usage info. These requirements help avoid medication errors, so patients get the right dosages at the right times. Good labeling also backs pharmaceutical protection solutions by giving key information about product ingredients, possible side effects, and storage needs.

Serialization and Traceability Requirements

Serialization in healthcare packaging is really crucial because of UDI (Unique Device Identification) rules from regulatory bodies. This system helps improve supply chain management by letting manufacturers track products from making them to delivering them to users. By using effective serialization, companies can lower the risks of counterfeit drugs or devices. This is important for good risk management in packaging processes.

Meeting International Packaging Standards

Meeting international packaging standards is key for doing well in global markets. FDA compliance makes sure that medical products meet safety guidelines. Also, Good Manufacturing Practice (GMP) packaging ensures quality assurance throughout production. Following these healthcare industry standards protects consumers and builds trust with those involved in distributing medical goods.

Ensuring Safety through Tamper-Proof Features

Tamper-proof features are must-haves for patient safety packaging. These designs stop unauthorized access and protect against contamination or tampering before a product reaches its final user. Additionally, child-resistant packaging boosts safety by keeping young children away from dangerous substances. This keeps families safe while sticking to regulatory rules.

Environmental Compliance and Sustainability

With growing concerns about the environment in healthcare, eco-friendly healthcare packaging has become really important for manufacturers. Using biodegradable materials cuts down on waste going to landfills. Meanwhile, recyclable options support sustainability efforts across many industries. By choosing environmentally friendly practices, companies can connect with modern consumer values without sacrificing quality or compliance.

VSL Packaging: Your Partner in Medical Packaging

Expertise in Healthcare and Pharmaceutical Packaging

At VSL Packaging, we know that good packaging is super important in healthcare and the pharmaceutical field. We focus on making sure all our medical device packaging and pharmaceutical packaging is top-notch. We follow FDA rules and Good Manufacturing Practices (GMP) when creating pharmaceutical packaging, medical packaging and healthcare packaging to keep our customer’s products safe and effective.

We take quality assurance of our medical packaging solutions very seriously as we know this is crucial to the reputation of healthcare professionals and contract drug manufacturing organizations. Each package goes through tough testing to ensure it stays safe and works well. By sticking to healthcare industry standards, we create reliable packaging solutions for healthcare professionals and medical industry leaders seeking the best patient outcomes. These medical and pharmaceutical packaging solutions not only protect sensitive medical products but also help them look good on the market.

Scalable Production for Varying Needs

Flexibility is key in today’s fast-paced medical supply chain to facilitate dynamic packaging lines and distribution. That’s why we offer production options that can grow with your needs. Whether you need small or large batches of durable healthcare packaging, we’ve got you covered with our range of packaging lines. Our custom healthcare packaging solutions are made with logistics in mind, which means they are easy to handle as they move through distribution channels.

We use high-quality materials that can take a beating during transport while still keeping your products safe. This way, your items arrive at their destination in perfect condition.

Commitment to Quality and Compliance

We care about quality at every stage of our work. Our approach includes managing risks in packaging processes. We stay informed about labeling requirements needed for different markets, including compliance labels for regulatory approval.

Serialization is key in healthcare packaging, and we excel here too. Our designs include tamper-proof features that make products safer from counterfeiting threats. This gives both manufacturers and consumers peace of mind.

Choosing VSL Packaging means working with a partner dedicated to high-quality product development and strict adherence to all relevant healthcare regulations.

FAQs about Medical & Healthcare Packaging

Q1: What is active packaging in medical applications?

Active packaging enhances the preservation of medical products. It interacts with the environment to extend shelf life. This type of packaging can absorb moisture or release antimicrobial agents.

Q2: How does logistics packaging ensure product safety?

Logistics packaging protects medical products during transport. It reduces risks from physical damage and contamination. Proper design and materials maintain product integrity through distribution.

Q3: Why is medical equipment packaging important?

Medical equipment packaging safeguards sensitive devices. It prevents damage and contamination during transit. Compliance with standards ensures that equipment remains sterile until use.

Q4: What are the benefits of medical supply packaging?

Medical supply packaging promotes safety and efficiency. It provides organization for supplies while ensuring compliance. Quality designs reduce waste and enhance usability.

Q5: How can custom die-cut packaging enhance branding?

Custom die-cut packaging allows brands to create unique shapes. It differentiates products on shelves and improves visual appeal. Clear branding builds consumer trust and recognition.

Q6: Why is e-commerce medical & healthcare packaging significant?

E-commerce healthcare packaging ensures safe delivery of products sold online. It protects items during shipping while meeting regulatory standards. Well-designed packaging enhances customer satisfaction upon receipt.

Q7: How do plant-based materials impact healthcare packaging?

Plant-based materials provide sustainable options for healthcare packaging. They help reduce environmental footprints while maintaining safety standards. Companies that use these materials improve their brand image.